Horizontal Directional Drilling

This trenchless method of installing pipelines is extremely protective to the environment. It does not involve a large working space and does not disrupt other works as well as urban traffic systems. It can be done at any time of the day and requires a shorter duration for completion, hence it is cost effective as compared to conventional open-trench methods.

The HDD technology involves the use of special drilling tools that can be precisely steered to avoid any obstructions for any pipeline crossing to be completed. This technology is flexible to adapt to any pipe size or length and pipe material necessary to be installed. HDD has been used to install pipelines carrying oil, natural gas, petrochemicals, water, electrical and network cables.

Our Capabilities In HDD

- Feasibility studies, project risk analysis, project planning for HDD projects

- HDD Construction Management Services, including equipment/tooling supply and technical personnel assistance

- HDD profile design, calculations and analysis

- Environmental risk assessment

- HDD equipment and tooling design, selection and consultancy services

Featured Project

Project Title: Procurement Construction and Commissioning (PCC) of Regasification Terminal 2 Pipeline Project (RGT2P)

client: PBJV Group Sdn Bhd

Completion Year : 2017

Description : 36” Diameter API Gas Pipe

Pipe Length : 600m +850m + 660m = 2110m

Formation: Rock

Approach: River Crossing

HDD Process & How It Works

01

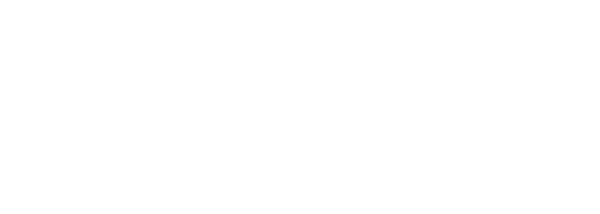

Pilot Hole Drilling

Using a suitable pilot hole drilling BHA (Bottom Hole Assembly), a small diameter pilot hole is drilled from the ground surface. The pilot hole BHA shall spud in at the entry point and drilled into the ground following a predetermined path crossing underneath the elements of obstruction (rivers, lakes, channels, roads, railways, runways, existing tunnels, marsh lands, shorelines and the like). The pilot hole drilling is completed as it punches out of the ground at the designated exit point.

02

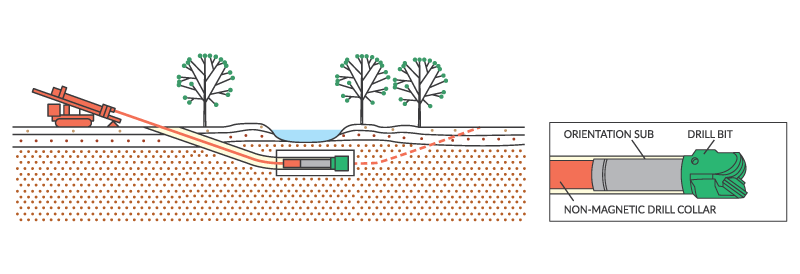

Reaming

As soon as the pilot hole drilling process is completed, the small diameter pilot hole shall be enlarged to accommodate the intended product pipe. This process shall be done by installing a larger diameter BHA and reaming it (by rotating while pulling or pushing) along the already drilled pilot hole. This process may come in stages / sizes depending on the final HDD borehole diameter designed for the product pipe.

03

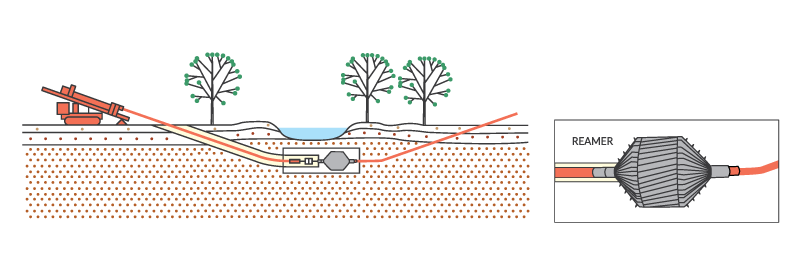

Pipe Pull Back

Upon completion of the reaming process, the product pipe shall be pulled in and installed inside the HDD borehole. This process is done by connecting a pulling head to the leading end of the product pipe and attaching the pulling head to the pullback assembly. The pullback assembly, together with the product pipe, shall then be pulled in the HDD borehole by the HDD Rig. The process is completed once the pullback assembly together with the product pipeline reaches the surface at the Rig side. The pullback assembly shall be dismantled from the product pipe for pipe tie-in or other works to follow.

"WE HAVE THE CAPABILITIES AND SUCCESSFUL HISTORY FOR HARD ROCK DRILLING."

We strive to serve our clients with the best equipment and machinery in the industry. Together with a team of capable mechanical engineers, we ensure that our machineries and equipment are well maintained, and fabricated to perform even the most challenging jobs. These machineries are always ready for a good run, without any technical downtime.

About Mersing

Mersing is a premier trenchless construction and engineering service provider founded in Malaysia, with a vast experience across 9 countries in Asia, an extensive fleet of drilling rigs accompanied by a dedicated team of engineers who are highly competent, knowledgeable and well trained in the fields of Horizontal Directional Drilling and Microtunneling.

Quick Links

Headquarters

84, Jalan SG 4/8, Taman Sri Gombak,

68100 Batu Caves,

Selangor Darul Ehsan

Malaysia

T : +603 6186 1333

F : +603 6188 8866

E : mmce@mersing-group.com