Pipe Jacking

Mersing’s second strength and expertise is in Pipe Jacking, it is another trenchless method where pipe strings are being connected unit by unit from their (launch shaft) till it reaches the length and destination required.

The hydraulic jacks would push the pipe string that is led by a cutter connected to the front of the pipe string, from the launch shaft towards the direction of the target shaft.

Pipe jacking is most ideal for new sewer construction it is also used for sewer replacement and relining, gas and water mains, oil pipelines, electricity and telecommunication installations, culverts and subways. Mersing has the capacity to drill up to 2,500 millimetres diameters and has drilled lengths up to 700 meters.

Our Capabilities In Pipe Jacking

- Planning and design of alignment and profile

- Analyse prediction of ground and tunnel deformation

- Assessment of effect of tunnel boring works on adjacent structures

- Construction advisory services

- Provide design optimization

- Consultancy on services in machineries and tooling selection

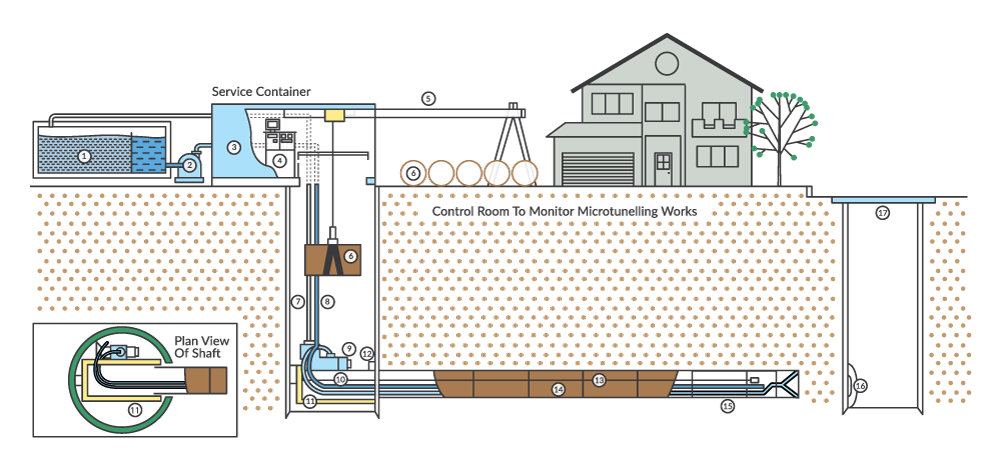

Pipe Jacking Process & How It Works

Step 1

Firstly, the virgin ground is being excavated to create a manhole pit, and the hydraulic jack is places at a strategic spot. The size and depth of the manhole pit varies, depending on the specification requirements.

Step 2

The pipes strings are stringed together piece by piece using the hydraulic jacking machine. Each unit of pipe are being lifted down into the manhole pit by a crane. The Jacking of pipes towards the destined direction is done from the launch shaft to the target shaft.

Step 3

Lastly, once the string of pipes are done, the crane will then, remove the cutter head from the manhole pit at the target shaft, and replace the gap with a connecting pipe inside. Both manhole pits will be sealed with cement seamlessly.

“We strive to serve our clients with the best equipment and machinery in the industry. Together with a team of mechanical engineers who ensures that our machineries and equipment are well maintained, and fabricated to perform even the most challenging conditions. These machineries are always ready for a good run, without any technical downtime.”

About Mersing

Mersing is a premier trenchless construction and engineering service provider founded in Malaysia, with a vast experience across 9 countries in Asia, an extensive fleet of drilling rigs accompanied by a dedicated team of engineers who are highly competent, knowledgeable and well trained in the fields of Horizontal Directional Drilling and Microtunneling.

Quick Links

Headquarters

84, Jalan SG 4/8, Taman Sri Gombak,

68100 Batu Caves,

Selangor Darul Ehsan

Malaysia

T : +603 6186 1333

F : +603 6188 8866

E : mmce@mersing-group.com